Philips GM2317 signal generator (1954)

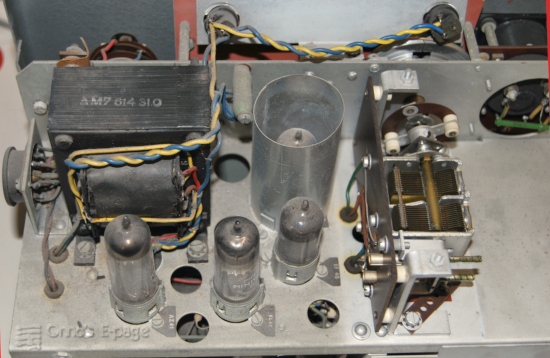

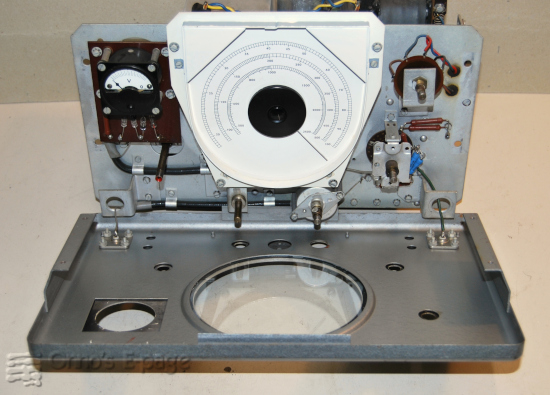

A view at the inside from the back.

The GM2317 uses the Wien-bridge oscillator principle. The valve line-up consists of Rimlock types:

| EF40 | pentode as pre-amplifier, |

| EF40 | pentode as second amplifier stage, |

| EL41 | power pentode as output stage, |

| AZ41 | rectifier. |

Except for the missing handle. the generator was in good condition. It had an inventory label on the front and a glue residue from a label exposing the text “ELEKTR.MEETT.” which is an abbreviation of “Electronic Measurement Technology (Laboratory)”. After checking the capacitors and slowly starting the generator to let the power supply electrolytics reform, it just worked. I found that the coupling capacitor from the first to the second stage was leaky, but I did not replace it at the time.

I have used it for years until I collected more AF generators to use. The GM2317 wasn't always stable as it should be. My notes say that the amplitude tended to vary and sometimes suddenly the signal was distorted. This may have just been the automatic gain control from the incandescent lamps swinging round the set point. Somewhere around 2015 the output meter stopped working and the tuning knob didn't work any more. So I put it on a shelf to fix it sometime later.

I checked manufacturing date codes on the capacitors and other components and found dates in 1954.

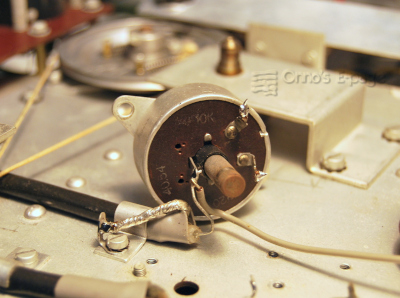

Manufacturing date code on volume pot.

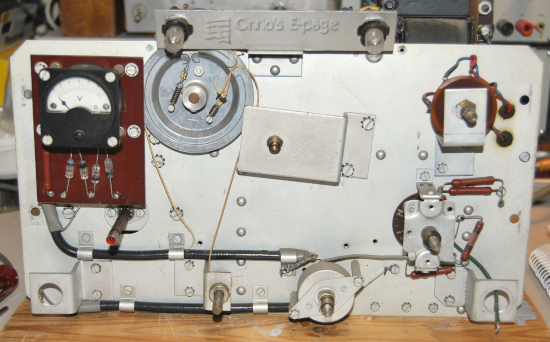

Front removed. Driving cord broken and more.

One of the resistors in the output divider was burned. Its resistance was too high. I replaced it by 2 precision resistors in parallel, to get the right value of 680Ω. When I measured its value and the other resistors, I noticed that the output meter moved only with the ohmmeter leads in one orientation, not when I swapped the leads. So I checked the four rectifier diodes of the output meter and indeed: one of the OA70 germanium diodes was interrupted. I replaced the defective diode and tested the meter. Was OK now.

Then I unsoldered the leads to the power supply electrolytic capacitors to reform and test them. This is necessary because there is a voltage divider (R49+R50) parallel to the + voltage to bias the heaters of the valves. Philips did this to avoid cathode-heater breakdown. The voltage divider varies from version to version but it is there in all GM2317 versions. Anyway, its presence in the circuit would disturb my leakage current measurements so I temporarily removed it. There was another difference from the original schematic: the series resistor R34 was 2k7, not 4k7. This would increase the power supply voltage for the pre-amplifier valves. It was clear that this was original because the ink dots on the solder joints were still in place. The electrolytic capacitors were good after an hour. I also reformed the output capacitor (a 50+50μF electrolytic like the power supply capacitor) and saw it was good up to 220V but above that its leakage current increased. This was enough for its function so I left it.

A view from the bottom after repairs.

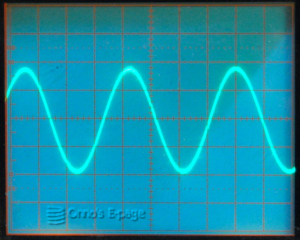

When I tested the generator, it just started to work. When switching frequency range, the signal would disappear, come up abruptly, get distorted and settle to a nice stable sine wave.

Checking the voltages it turned out that the power supply voltage was only 220V instead of 270V. I replaced the AZ41 and got 275 V. This is as specified for the GM2317. The GM2317/01 and later have 300V, but those have a different power transformer and an EZ80 rectifier valve.

Now the cathode voltage of the EL41 was a bit low. I saw that the getter mirror on the second EF40 was very thin, possibly indicating wear. I replaced it, getting a slightly lower anode voltage. There was a +1V on its grid so it drew too much current (3&nbps;mA instead of 2). The anode is DC-coupled to the EL41 so it also offsets the cathode voltage of the output valve. The cause was the leaky paper capacitor C11 between first and second stage. I replaced it by a Philips mylar capacitor.

When turning the output level control, it cracked. It was dirty inside. I unmounted it, sprayed a drop of mild contact cleaner inside and turned it a few times. Reattached it and the cracking was gone. I also cleaned the contacts of the range control resistor carrousel. There was some brownish sticky goo on them, exactly like the pollution on the contacts of the GM2885 oscillator I finished two weeks before. I suspect this is dried-out contact grease Philips originally had applied. I cleaned then using isopropyl alcohol first, then ammonia and finally applying fresh contact grease to the contacts. They should be fine for the next 50 years.

All repairs done. Front and knobs to be mounted.

There was a last cosmetic aspect to cure: the rim of the frequency scale had small rust specks. The scale itself was looking good. The rust would gradually become worse. So to stop that, I disassembled the scale and its rim, sanded the rim, treated it with metal primer and then creamy white paint. I reattached the rim to the scale and then the scale to the front of the chassis and the indicator to the tuning capacitor.

Almost done.

Then I resoldered the wires to the BNC-connectors and reattached the front. After cleaning, I mounted the knobs and reassembled the cabinet. This was looking good!

The GM2317 and removed components.

Copyright © 2004, 2026 by Onno's E-page published 2004-03-19, last updated 2026-01-16